Choose AquaSust Professional Wastewater Treatment Experts

membrane bioreactor

Membrane bioreactor(MBR)

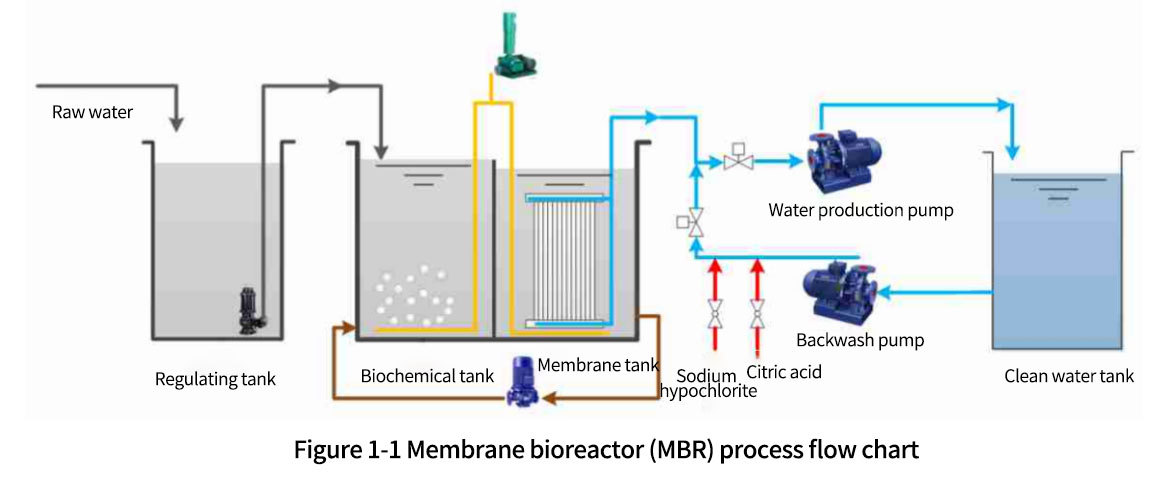

Membrane Bioreactor (MBR) technology provides an innovative sewage treatment and reuse process, organically combining membrane separation technology with traditional biological treatment technology for treatment and reuse of sewage waste water. Recently, international water treatment technology has attracted greater interest. Membrane separation equipment is installed within the reactor and used to filter muddy sewage in order to intercept activated sludge and macromolecular organic matter, achieve separation of mud from water, increase concentration of activated sludge in the reactor and further improve degradation efficiency by biochemical reaction. Membrane bioreactor technology combines membrane separation and biochemical treatment technologies for an impressive combination of efficiency and effluent quality, making it one of the world's most advanced and promising new approaches for wastewater treatment.

Working Principle

Membrane Bioreactor(MBR) technology works on the basic principle of using water molecules to treat wastewater by exploiting their permeability in aqueous solution. By employing Membrane bioreactor technology's separation membrane, water molecules in sewage can be separated without disrupting passage of substances; external forces then act to push permeate through, effectively extracting pure water while meeting treatment goals while improving water quality and protecting the environment. Membrane bioreactor technology has become widely utilized for treating wastewater and has demonstrated great success, due to being a new type of technology able to increase energy conversion rate and separation efficiency on account of its non-changing membrane, thus better treating sewage.

Introduction to the functions of each part of the MBR system

1、 Membrane assembly: The membrane assembly replaces the secondary sedimentation tank in the traditional activated sludge process, and can perform efficient solid-liquid separation. The effluent water quality is good, and the secondary sedimentation tank is omitted, which reduces the land occupation; the efficient interception of microorganisms is conducive to the interception and growth of slow-growing microorganisms such as nitrifying bacteria, improving the nitrification efficiency of the system, prolonging the hydraulic retention time of certain difficult-to-degrade organic matter, and improving the degradation efficiency of difficult-to-degrade organic matter. On the other hand, it realizes the complete separation of the HRT and SRT of the reactor, and the operation control is flexible and stable, maintaining a high sludge concentration in the reactor, reducing the sludge load and the residual sludge production.

2、Aeration device: An aeration pipeline is set under the membrane assembly. The aeration method is perforated aeration. While ensuring the oxygen supply of the sludge, it will also fully flush the membrane surface, reduce the pollution of the membrane surface, make it less likely to be blocked, and extend the membrane cleaning interval. The drainage pipeline is used to discharge the mud or water accumulated in the aeration pipeline caused by abnormal conditions such as the fan stopping.

3、 MBR effluent pipeline: The filtration of wastewater through the micropores on the membrane surface can remove SS and most bacteria, fungi, colloids and some macromolecular organic matter. The filtrate is discharged through the MBR effluent pipeline by the negative pressure suction of the suction pump. The effluent can be reused, discharged or enter the next level of treatment facilities for further treatment according to the design requirements. Since sludge agglomerates will accumulate on the membrane surface during continuous suction, accelerating the rise of pressure, the normal operation is intermittent operation mode, generally 8-10 minutes of continuous operation and 2 minutes of stop.

4、Backwash pipeline: Membrane pollution is inevitable in the membrane separation process. During operation, the membrane is cleaned in time through the backwash pipeline, which effectively reduces membrane pollution, maintains membrane flux and prolongs the service life of the membrane.

Advantages of the Aquasust Membrane bioreactor

1. Its separation effect far surpasses traditional sedimentation tanks; effluent water quality is excellent with suspended solids and turbidity nearing zero; resource utilization from wastewater use; MBR process eliminates secondary sedimentation tank which significantly decreases floor space;

2. Thanks to the efficient interception effect of membrane, microorganisms can be completely intercepted in the bioreactor and its hydraulic retention time (HRT) and sludge retention time (SRT) can be divided distinctly, providing more flexible and stable operation control;

3. The mechanical interception effect of membrane prevents microorganism loss, while simultaneously maintaining a higher concentration of activated sludge within the bioreactor, increasing volume loads, decreasing sludge load, lowering residual production rates and ultimately reducing treatment costs.

4. It promotes the interception and growth of slow-growing microorganisms such as nitrifying bacteria, thus increasing nitrification efficiency of the system. In addition, this process increases hydraulic retention time of some hard-to-degrade organic matter in the system while effectively retaining microorganisms that decompose it - ultimately improving degradation efficiency for hard-to-degrade organic matter;

5. Membrane bioreactors offer simple automatic control and straightforward operations and management;

6. The membrane bioreactor can filter out harmful organisms like bacteria and viruses without the need for disinfection equipment, dosing, or residual chlorine control - making management and operation simpler, as well as saving costs associated with disinfecting.

List of main equipment and instruments of MBR system

|

Serial number

|

Equipment name

|

Specification model

|

Quantity | Unit |

Remarks

|

|

1

|

MBR membrane module

|

—— ——

|

—— —— | set |

Select according to the amount of water treated and the quality of the effluent

|

2 | Fan | —— —— | 2 | set | The aeration of the membrane area is calculated according to the aeration volume and the number of membrane components; generally 2 units, 1 in use and 1 in reserve |

3 | Suction pump | —— —— | —— —— | set | Select according to the amount of treated water and the outlet location. According to the number of membrane components, generally 2 units are selected, 1 in use and 1 in reserve |

4 | Float level gauge | —— —— | 2 | set | Linked with the membrane suction pump, high start and low stop |

5 | Flow meter | —— —— | 1 | set | Select according to the amount of treated water |

6 | Vacuum pressure gauge | -0.1~0MPa | —— —— | set | The same as the number of commonly used suction pumps, used to indicate the suction pressure of the membrane outlet water |

7 | Time relay

or PLC | —— —— | —— —— | set | Control the operation of the suction pump, the operation time of the suction pump is 8~10min, and the stop operation is 2min |

8 | Pressure gauge | 0~0.6MPa | 1 | set | Used to indicate the backwash water pressure |

|

9

|

Backwash dosing equipment

|

—— ——

|

1 | set |

The drugs added for online drug washing are generally sodium hypochlorite and citric acid, and the dosing pump and dosing box need to be configured respectively

|

|

10

|

Backwash pump

|

—— ——

|

1 | set |

The flow rate is generally twice the membrane outlet water

|

Application of Membrane bioreactor

1、Application of Membrane bioreactor technology in domestic sewage

The main treatment object of sewage treatment facilities is urban sewage. Due to the high requirements for sewage treatment and the small amount of construction land, urban sewage treatment plants can use the Membrane bioreactor technology to treat sewage. After treatment, the quality of domestic sewage can be guaranteed, ensuring the stability of the effluent of the sewage treatment plant. When using Membrane bioreactor technology to treat urban domestic sewage, it is necessary to examine the removal effect of membrane bioreactors on ammonia nitrogen and turbidity in domestic sewage to ensure the efficiency and quality of sewage treatment.

2、 Application of Membrane bioreactor technology in pharmaceutical wastewater

Due to the complex internal composition and many types of organic pollutants, pharmaceutical wastewater will bring more serious pollution problems. When Membrane bioreactor technology is used to treat pharmaceutical wastewater, it mainly has the advantages of low energy consumption and small land occupation. Compared with other types of sewage, pharmaceutical wastewater has a higher concentration of pollutants and is a more difficult type of sewage treatment. By using Membrane bioreactor technology to recycle and utilize pharmaceutical wastewater, economic development can be smoother.

3、 Application of Membrane bioreactor technology in beer wastewater

Beer wastewater has the characteristics of relatively low nitrogen and phosphorus content, and the organic matter content in beer is relatively high. By using Membrane bioreactor technology to treat beer wastewater, ammonia nitrogen and SS in beer wastewater can be effectively removed, and the removal effect can be improved. When treating beer wastewater, it is necessary to improve the removal rate of ammonia nitrogen to ensure the quality and efficiency of beer wastewater treatment.

4、 Application of Membrane bioreactor technology in aquaculture and slaughtering wastewater treatment

The aquaculture industry will produce a lot of aquaculture and slaughtering wastewater, and the pollution problem is relatively serious. In addition, the aquaculture water contains a large amount of organic matter and nutrients such as nitrogen and phosphorus during aquaculture. Although agricultural production can be carried out, if the wastewater is not treated, it will cause serious environmental pollution. Therefore, it is necessary to flexibly use Membrane bioreactor technology and use this technology in the treatment of aquaculture and slaughtering wastewater to improve the quality and efficiency of wastewater treatment.

1 products found

ViewList

A membrane bioreactor offers numerous advantages over conventional wastewater treatment systems: By installing a membrane filtration process together with an activated sludge reactor, a higher organic matter removal performance is obtained. The quality of the output water is higher and remains constant.

FavoritesStart Your Wastewater Treatment Solution Now

With 20 years of wastewater treatment experience, AquaSust is the trusted expert in biochemical pool solutions. If you have any questions about wastewater treatment, please contact us and we will provide you with the best solution.

Industry Recognition

Trusted Certification

Choose AquaSust Professional Wastewater Treatment Experts

Contact Person

Please send your message to us

- Name

- *Title

- *Content