Traditional recipe

| Material | Quantity | Remark |

|---|---|---|

| EPDM | 100 | ENI 4049 |

| Carbon black N660 | 60 | Suzhou Baohua |

| P-500 | 40 | Paraffin oil plasticizer |

| Zinc oxide | 6.0 | |

| S.A1801 | 1.0 | |

| M | 0.8 | |

| BZ | 1.5 | |

| TT | 0.5 | |

| S | 0.8 |

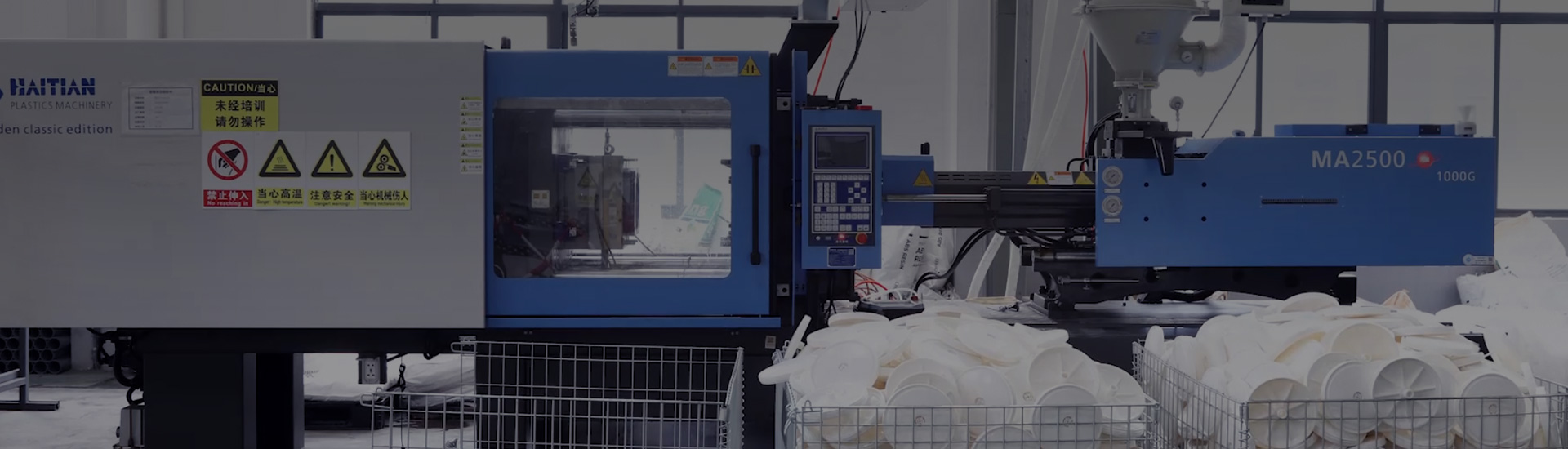

Factory area

high-speed extruded and injection lines

Annual production capacity of MBBR

Cooperating countries

| Material | Quantity | Remark |

|---|---|---|

| EPDM | 100 | ENI 4049 |

| Carbon black N660 | 60 | Suzhou Baohua |

| P-500 | 40 | Paraffin oil plasticizer |

| Zinc oxide | 6.0 | |

| S.A1801 | 1.0 | |

| M | 0.8 | |

| BZ | 1.5 | |

| TT | 0.5 | |

| S | 0.8 |

| Material | Quantity | Remark |

|---|---|---|

| EPDM | 70 | ExxonMobil 8600 |

| EPDM | 30 | Keltan4450 |

| Carbon black N550 | 50 | Cabot |

| N774 | 20 | Cabot |

| Organic zinc | 3.0 | Complexes of antetralate and zinc compounds |

| S.A1801 | 0.5 | |

| Oleamide | 1.0 | (Z)-9-octadecenoic acid amide |

| DCP | 4 | |

| TAIC | 2 | |

| S | 0.3 |

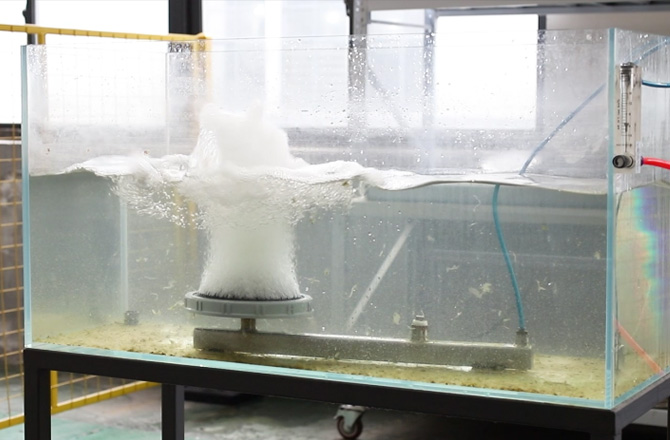

The Aeration diffuser is designed based on the specific application requirements, taking into account factors such as the desired amount of aeration, liquid volume, and operating conditions.

The appropriate material for the disc diffuser is selected based on its chemical compatibility with the liquid being treated, temperature range, and other factors such as durability and flexibility.

A tool is created to produce the perforations or slots in the Aeration using a process such as laser cutting, punching, or molding.

The Aeration is fabricated using the chosen material and the perforation tool. The mounting mechanism or connector may also be added at this stage.

The disc diffuser is tested to ensure that it meets the desired performance specifications, including diffusion efficiency and pressure drop.

The only disc diffuser factory in China that use Robot Arm. We introduced 100% brand new high-tech automated production equipment, all the goods are filled in and pick out by Robot arm, which makes the speed and plasticizer time more precise, control the quality better than by hand.

Unique Material Anti-blocking Design: No hole clogging risk for 8 years Bimodal Molecular Weight EPDM Original Gum: Reduced Ventilation Resistance 20% Platinum Hydrosilylation Reaction Sulfurization: Tear strength increased to above35KN/M Oil-free Formula Design: 5-year elastic decay<20% rate

We very much welcome you to come to the AquaSust factory for on-site inspection. If you are interested, please make an appointment with us.