Diversity:

Municipal sewage comes from complex sources, including residential sewage, and commercial and industrial wastewater. This sewage may contain various organic and inorganic substances, such as food residues, grease, chemicals, heavy metals, microorganisms, etc.

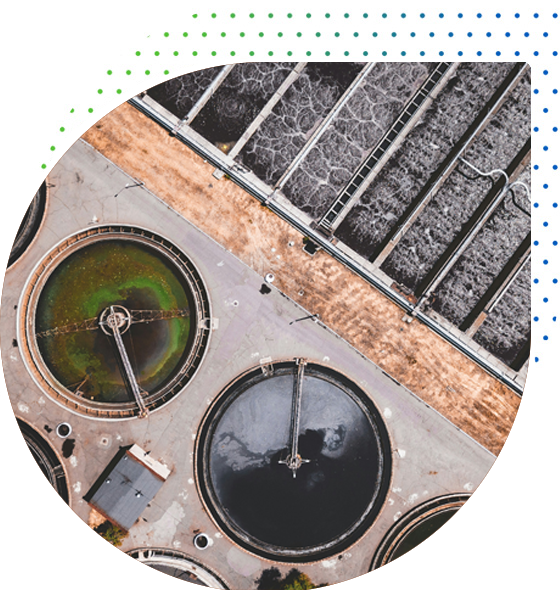

Large scale:

The amount of municipal sewage generated is usually large because cities have large populations and contain many industrial and commercial activities. This makes wastewater treatment a large and complex task

Fluctuation:

The amount of sewage produced may fluctuate greatly at different times and locations, such as working days and weekends, day and night, holidays, etc. This requires a certain degree of flexibility and adaptability in the sewage treatment system.

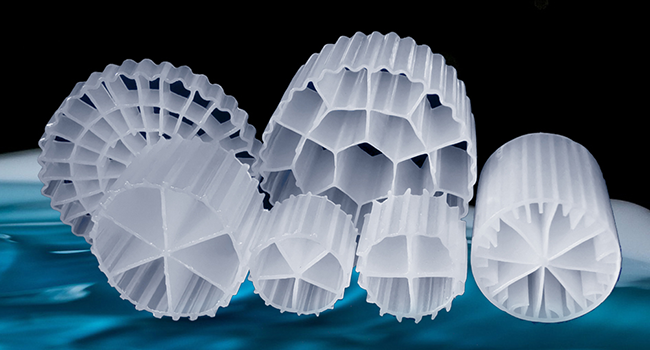

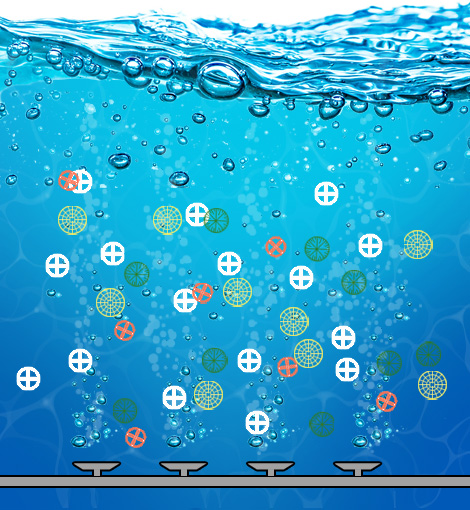

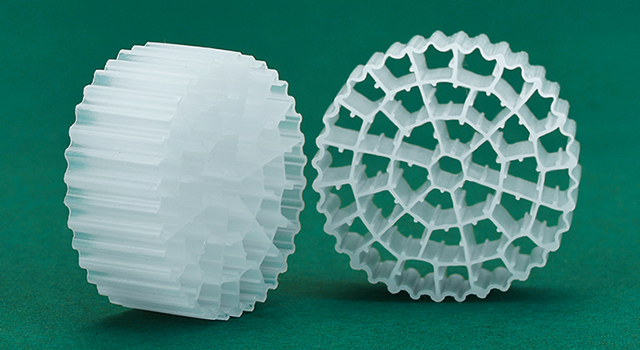

Complexity:

Sewage contains various complex chemical components, including organic matter, nitrogen compounds, phosphates, microorganisms, etc. Treating municipal wastewater requires a multi-stage treatment process to remove or reduce the concentration of these pollutants.