Order Production

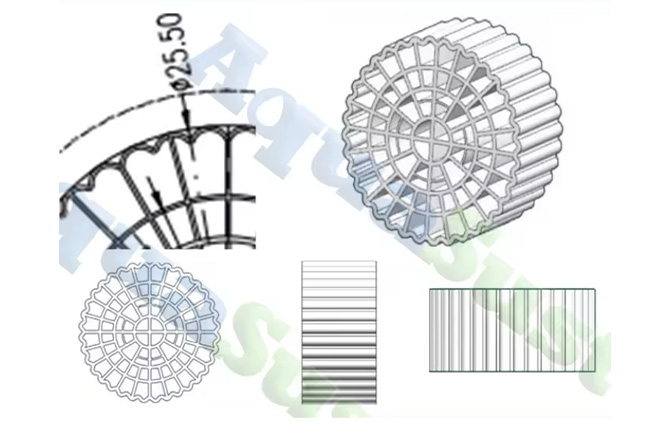

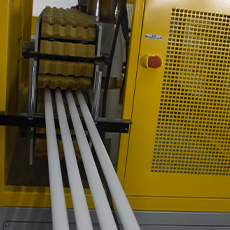

Starting with order-based production, the raw material is processed by precise machines into specific shapes and sizes to form the MBBR media.

Factory area

high-speed extruded and injection lines

Annual production capacity of MBBR

Cooperating countries

Starting with order-based production, the raw material is processed by precise machines into specific shapes and sizes to form the MBBR media.

Strict production control is applied throughout the production process to ensure quality and consistency of the product.

The finished MBBR media undergoes a detailed quality inspection, which may include dimensional measurements and ensuring that the shape of each media conforms to the design specifications.

Qualified MBBR media is packaged to ensure safety and protection during transportation.

The inspected products are stored in the warehouse ready for shipment.

We are a production-oriented factory, and advanced equipment is the basis for quality assurance. Try to use the control of the device to reduce the chance of human error. Use equipment to improve production efficiency and reduce labor intensity.

Utilize professional experience, shorten the length of the supply chain, and provide customers with after-sales service.

We very much welcome you to come to the AquaSust factory for on-site inspection. If you are interested, please make an appointment with us.