Choose AquaSust Professional Wastewater Treatment Experts

MBR System

Aquasust not only provides professional wastewater treatment equipment, but also customizes solutions for your wastewater treatment process or product problems. You are welcome to contact our wastewater treatment engineer Kate and let her solve your problem.

If you don't find a product that suits your situation, please contact us and we will provide you with a customized solution

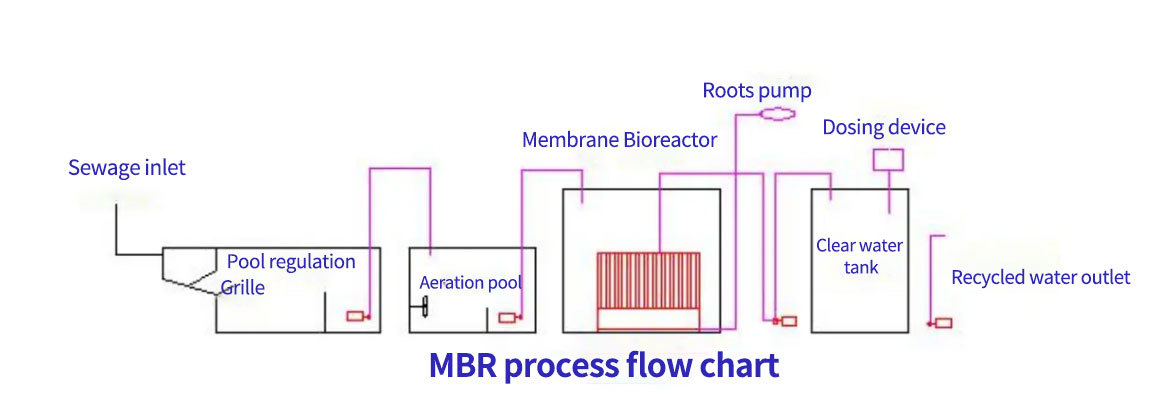

MBR system process flow overview

The MBR sewage treatment system usually consists of three parts: a regulating tank, a biological aeration tank, and a clean water tank. The sewage is removed from large particle impurities through a grille and enters the regulating tank. It is lifted by a sewage lifting pump and enters the facultative reaction tank to remove ammoniacal nitrogen. (When the ammonia nitrogen content in the sewage is relatively high, it is recommended to use a facultative reaction tank. Optional) Then, it enters the membrane biological aeration tank. In the membrane bioreactor, the organic pollutants in the sewage are degraded by microorganisms to generate water with COD up to standard, and then the water treated by the separation membrane with a large number of micropores on the surface is separated from the microorganisms in the pool. The reclaimed water obtained after treatment is stored in the middle water tank. In addition to being reused, the reclaimed water in the middle water tank is also used for backwashing of the membrane module. In order to prevent the growth of algae and bacteria, a small amount of reagent should be regularly put into the middle water tank.

Design of membrane flux

It should be calculated according to the residence time and the BOD volume load respectively, and the larger value should be taken. Generally, when treating domestic sewage, the residence time is 4 to 6 hours; the BOD volume load is 1.2 kg/(m^3·d); when treating other high-concentration organic wastewater, various parameters need to be determined through experiments. When requiring denitrification and dephosphorization, in addition to considering BOD, the residence time required for denitrification and dephosphorization should also be considered.

Requirements for the placement of membrane modules

When setting up membrane modules in the MBR membrane pool, the planar configuration is to ensure that the activated sludge mixed liquid in the MBR membrane pool can generate a uniform circulating flow. The planar layout of the MBR membrane components should be located as close to the center of the MBR membrane pool as possible, and ensure sufficient distance in front, back, left and right. Ensure a distance of more than 300m in front, back, left and right of the MBR membrane box; the distance between the top of the MBR membrane box and the water surface (minimum water level) should be at least 500mm.

Operation and Management of MBR Membrane System

1.Keep the following parameter records:

2.In the membrane pool: water temperature, pH value (PH), aeration amount, dissolved oxygen (DO), sludge concentration (MLSS), sludge settling performance (SV), sludge viscosity, excess sludge discharge amount, biological oxygen demand (BOD), chemical oxygen demand (COD), total nitrogen (TN), total phosphorus (TP). MBR effluent: effluent flow rate, vacuum pressure gauge value, turbidity, suspended solids (SS), BOD, COD, total ammonia (TN), total phosphorus (TP).MBR membrane module cleaning:

I. Physical cleaning:

(1) Online air-water scrubbing:

Cleaning equipment: blower.

Frequency: continuous for 24 hours. During the operation, it is required that the self-priming pump discharges water for 8 minutes and stops for 2 minutes for intermittent effluent aeration cleaning.

(2) Online water backwashing:

Cleaning equipment: backwash pump.

Frequency: work for 29 minutes, backwash for 1 minute.

Cleaning solution formula: MBR effluent or tap water.

II. Chemical cleaning:

Chemical cleaning includes online chemical cleaning and offline chemical cleaning (immersion cleaning), among which online chemical cleaning includes maintenance cleaning and restoration cleaning.

Te MBR system is mainly blocked by organic matter, and sodium hypochlorite is usually used as the chemical solution; at the same time, there will also be inorganic blockage after long-term use, so acid should be appropriately used for cleaning; finally, due to the deposition of pollutants in the environment, the growth of microorganisms and the pollutants from the loss of the system during long-term operation or suspension of operation, sodium hypochlorite or sodium hydroxide can be used for cleaning.

1 products found

ViewList

A membrane bioreactor offers numerous advantages over conventional wastewater treatment systems: By installing a membrane filtration process together with an activated sludge reactor, a higher organic matter removal performance is obtained. The quality of the output water is higher and remains constant.

FavoritesStart Your Wastewater Treatment Solution Now

With 20 years of wastewater treatment experience, AquaSust is the trusted expert in biochemical pool solutions. If you have any questions about wastewater treatment, please contact us and we will provide you with the best solution.

Industry Recognition

Trusted Certification

Choose AquaSust Professional Wastewater Treatment Experts

Contact Person

Please send your message to us

- Name

- *Title

- *Content