MBBR Mixer

Low Speed Mixer Performance Parameters

Aquasust MBBR Mixer are designed in such a way that they have an exceptionally large, inner surface area on which the bacteria can grow without being knocked off or otherwise destroyed when they rotate and hit each other.

Model | Power (KW) | Electrode | Rated Current (A) | Speed (R/Min) | Quantity (Set) | Diameter (Mm) | Threst (N) | Weight (Kg) |

| AS-MIXER3/4 | 3 | 4 | 6.6 | 420 | 2 | 400 | 1400 | 75 |

| AS-MIXER4/4 | 4 | 4 | 8.6 | 420 | 2 | 550 | 1800 | 85 |

| AS-MIXER5.5/4 | 5.5 | 4 | 11.8 | 420 | 2 | 550 | 2100 | 90 |

| AS-MIXER7.5/4 | 7.5 | 4 | 15.5 | 420 | 2 | 620 | 2600 | 100 |

| AS-MIXER11/4 | 11 | 4 | 24 | 420 | 2 | 750 | 3100 | 120 |

| AS-MIXER15/4 | 15 | 4 | 33 | 420 | 2 | 800 | 3500 | 150 |

Aquasust MBBR Mixer is specially developed for gentle mixing of the liquid plastic carrier elements (biomedia) in MBBR tanks.

The liquid biomedia used in the MBBR processes in modern sewage treatment plants is usually made of HDPE like Aquasust MBBR Media.

1.Lower Impeller Speed: The mixer has a lower impeller speed, only 106 revolutions per minute (r/m), compared to the typical 400 to 1000 r/min of a submersible mixer. This slower speed, approximately 10 to 20% of the typical speed, is tailored to meet the specific process requirements of the bio-carrier tank.

2.Large Diameter Three-Leaf Blades: The mixer features large diameter three-leaf stainless steel blades. This design is carefully selected to meet both hydraulic and biocarrier process requirements within the tank. The size and material of the blades contribute to efficient mixing and durability, important factors in wastewater treatment systems.

3.Self-Cleaning Propeller: The propeller is designed for self-cleaning functionality. Constructed from stainless steel material, it not only ensures durability but also incorporates features for automatic cleaning. This design consideration enhances the longevity and effectiveness of the mixer in maintaining optimal performance over time.

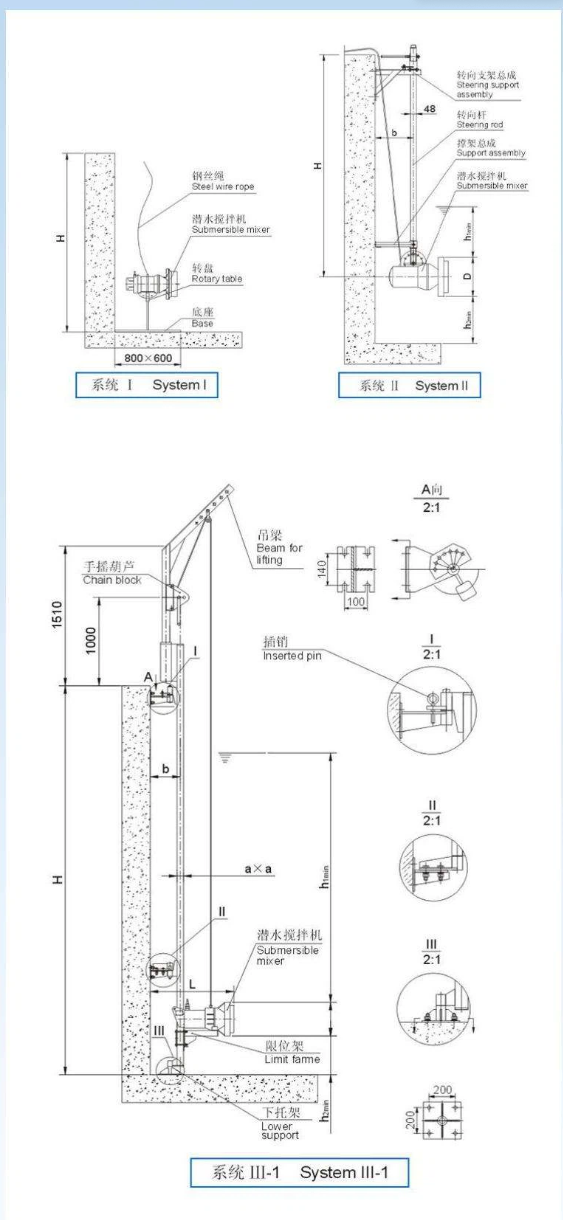

4.Versatile Installation System: Equipped with an installation system developed by Aquasust, the mixer can be installed on the equipment from multiple angles. This flexibility in installation enables efficient and adaptable integration into various configurations of the bio-carrier tank, optimizing space utilization and overall system effectiveness.

| Model | Motor Power (Kw) | Electrode | Rated Current (A) | RPM Of Vane Or Propellel (R/Min) | Diameter Of Vane Or Propeller (Mm) | Weight (Kg) |

| AS-QJB0.37/6 | 0.37 | 6 | 4 | 980 | 220 | 25 |

| AS-QJB0.85/8 | 0.85 | 8 | 3.2 | 740 | 260 | 55 |

| AS-QJB1.5/6 | 1.5 | 6 | 4 | 980 | 260 | 55 |

| AS-QJB2.2/8 | 2.2 | 8 | 5.9 | 740 | 320 | 88 |

| AS-QJB 4/6 | 4 | 6 | 10.3 | 960 | 320 | 88 |

| AS-QJB1.5/8 | 1.5 | 8 | 5.2 | 740 | 400 | 74 |

| AS-QJB2.5/8 | 2.5 | 8 | 7 | 740 | 400 | 74 |

| AS-QJB 3/8 | 3 | 8 | 8.6 | 740 | 400 | 74 |

| AS-QJB 4/6 | 4 | 6 | 10.3 | 980 | 400 | 74 |

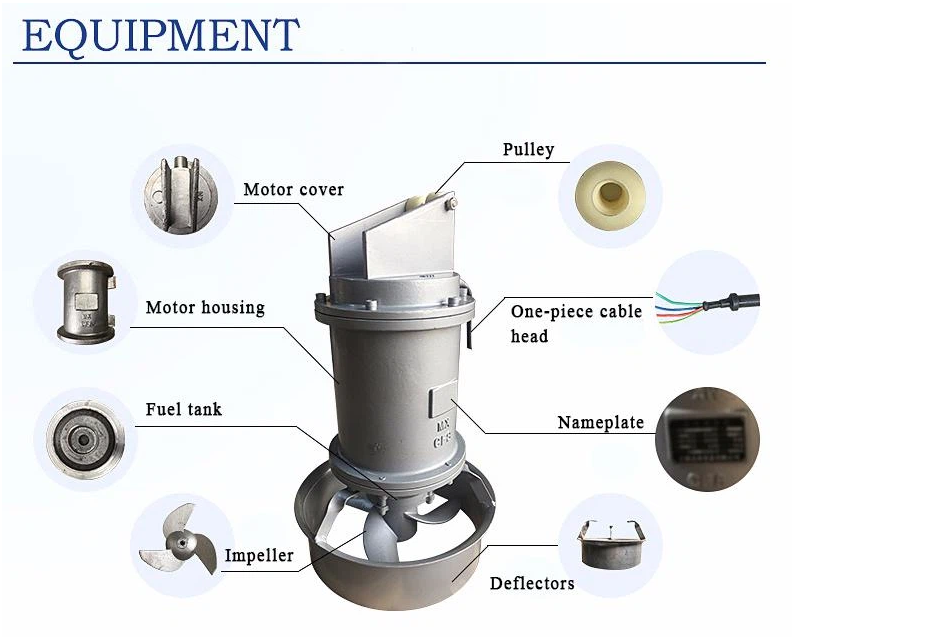

Aquasust Submersible Mixer Feature:

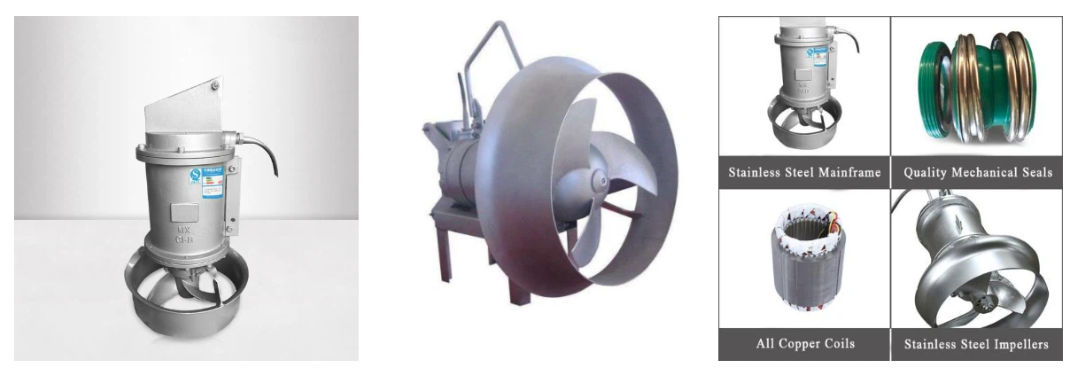

1.The Aquasust submersible mixer features a compact structure, small volume, and lightweight design, ensuring ease of handling, installation, and maintenance. With simple operation and maintenance procedures, it offers long-lasting performance.

2.Its impeller structure is meticulously designed for optimum hydraulic performance, resulting in high work efficiency. Equipped with a self-cleaning function, the swept blade design prevents debris accumulation and potential jamming.

3.When paired with an aeration system, the mixer achieves significant energy savings while enhancing oxygenation and preventing sedimentation issues.

4.The motor boasts insulation class F and IP68 protection grade, along with imported maintenance-free bearings and advanced safety features such as oil chamber leak detection and exclusive patented motor winding overheating protection and condensation prevention, ensuring safe and reliable operation.

5.Featuring two independent mechanical seals made of corrosion-resistant materials like carbide carbon, silicon, and stainless steel fasteners, the mixer ensures durability and reliability in harsh conditions.

6.A unique cable seal design eliminates potential cable leakage issues, enhancing safety and reliability.

7.Utilizing why separation technology for standard parts effectively prevents corrosion, enhancing the longevity and performance of the mixer in corrosive environments.

1.The Aquasust submersible mixer features a compact structure, small volume, and lightweight design, ensuring ease of handling, installation, and maintenance. With simple operation and maintenance procedures, it offers long-lasting performance.

2.Its impeller structure is meticulously designed for optimum hydraulic performance, resulting in high work efficiency. Equipped with a self-cleaning function, the swept blade design prevents debris accumulation and potential jamming.

3.When paired with an aeration system, the mixer achieves significant energy savings while enhancing oxygenation and preventing sedimentation issues.

4.The motor boasts insulation class F and IP68 protection grade, along with imported maintenance-free bearings and advanced safety features such as oil chamber leak detection and exclusive patented motor winding overheating protection and condensation prevention, ensuring safe and reliable operation.

5.Featuring two independent mechanical seals made of corrosion-resistant materials like carbide carbon, silicon, and stainless steel fasteners, the mixer ensures durability and reliability in harsh conditions.

6.A unique cable seal design eliminates potential cable leakage issues, enhancing safety and reliability.

7.Utilizing why separation technology for standard parts effectively prevents corrosion, enhancing the longevity and performance of the mixer in corrosive environments.

Aquasust MBBR Mixer And Submersible Mixer Use In The Following Conditions:

1.The highest medium temperature does not exceed 40℃.

2.The PH value is between 5 and 9.

3.The density of liquid shall not exceed 1.15 kg/m3.

4.Long-term diving operation, the diving depth is generally not more than 20m.

Application Examples:

1.MBBR reactors

2.Fish ensilage

3.Acidic liquids

4.Liquids with a high chloride content

5.Desalination plants

6.Anoxic and anaerobic tanks

7.SBR reactors

8.Sludge tanks

FAQ

1.Can We Get Samples?

Yes, 1kg free samples can supply .

2.What's Your Delivery Time?

Normally 15-20days afater order confirm.

3.What Is MOQ?

Our MOQ is 1PCS .

4.Are You Factory Or Trading Company?

We’re a direct factory in Anqing Anhui China.

5.How About Container Quantity?

1*20GP can load 30CBM 1*40GP can load 70cbm

6.What's Your Packing?

Packing is woven bag;0.1m3/1m3 per bag

Start Your Wastewater Treatment Solution Now

With 20 years of wastewater treatment experience, AquaSust is the trusted expert in biochemical pool solutions. If you have any questions about wastewater treatment, please contact us and we will provide you with the best solution.

Industry Recognition

Trusted Certification

- Name

- *Title

- *Content