Choose AquaSust Professional Wastewater Treatment Experts

Home / All / MBBR System / MBBR Media /

AS-MBBR38 MBBR Media For Pulp And Paper Industry Wastewater Secondary Treatment

AS-MBBR38 MBBR Media For Pulp And Paper Industry Wastewater Secondary Treatment

| Categories | MBBR Media |

|---|---|

| Brand | AquaSust Wastewater Treatment Solutions |

| Model | AS-MBBR38 |

| Membrane-Forming Time | 3-15days |

| Applicable Temperature | 5-60℃ |

| Life Span | More than 20 years |

| Unit Price | US $ 136-146 / cubic meter |

| FOB port | Shanghai |

| Terms of Payment | L/C, D/A, D/P |

| Update Time | Apr 4,2025 |

Detail Information

MBBR Media AS-MBBR38 Introduction

Category: Biochemical Tank - MBBR Media

Band: AquaSust

Model: AS-MBBR38

Size: Φ25*10mm

Material: 100% White Virgin HDPE

Densilty: 0.96-0.98g/cm3

Surface Area: >800m2/m3

Membrane-Forming Time: 3-15days

Applicable Temperature: 5-60℃

MBBR Media AS-MBBR38 Advantage

1. Efficient removal of pollutants: The media has the ability to efficiently remove pollutants from wastewater, ensuring high quality of wastewater treatment.

2. Resistance to chemical environments and impacts: The AS-MBBR38 media is able to remain stable in chemical environments and is impact-resistant, ensuring continuous stability of operation.

3. Compact design and scalability: The compact design makes it an ideal choice for plants with limited space, while having good scalability and being able to be expanded and adjusted as needed.

4. Easy integration into existing systems: The media can be easily integrated into existing wastewater treatment systems without large-scale modifications, saving time and costs.

5. Flexibility to adapt to production changes: The AS-MBBR38 media is able to flexibly adapt to changes in the production process, ensuring the continuity and stability of wastewater treatment.

6. Low maintenance and operating costs: The system has low maintenance requirements and operating costs, reducing the long-term expenses of the plant.

7. Improved effluent quality: By improving the quality of wastewater effluent, the AS-MBBR38 media contributes to environmental sustainability and meets environmental regulations and standards.

8. Adaptability to various temperatures and wastewater types: The media has good adaptability to various temperatures and wastewater types, further highlighting its wide application and practicality in the pulp and paper industry.

MBBR Media AS-MBBR38 Application

The adoption of MBBR technology for secondary treatment in the pulp and paper industry represents a significant advancement in managing wastewater efficiently and sustainably. This industry is known for generating large volumes of wastewater with high levels of organic matter, suspended solids, and potentially toxic substances. Implementing AS-MBBR92 provides an efficient and effective solution for reducing these contaminants. The process utilizes small, plastic carriers that move freely within the reactor, providing a surface for biofilm growth. These biofilms house microorganisms that degrade organic pollutants, effectively lowering BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) levels in the wastewater.

Moreover, AS-MBBR38 is highly adaptable and can handle fluctuations in wastewater volume and composition, which are a common occurrence in the pulp and paper industry. This resilience, combined with the compact design of AS-MBBR38, makes them ideal for facilities looking to upgrade their wastewater treatment plants without requiring significant additional space. Additionally, the AS-MBBR38 operates with minimal sludge production and lower energy consumption compared to traditional treatment methods, aligning with the industry's growing commitment to environmental sustainability and operational efficiency.

In essence, the application of AS-MBBR38 for secondary wastewater treatment in the pulp and paper industry not only enhances the removal of harmful pollutants but also contributes to water conservation efforts. By improving the quality of effluent, these systems support the industry's compliance with environmental regulations and promote the reuse of treated wastewater, further reducing the ecological impact of pulp and paper production processes.

Parameter

|

Mbbr Media(Type)

|

Diameter * Height(mm)

|

Surface Area(m2 / m3) |

Inside Void Size (mm) | Number of units per m3 |

|

AS-MBBR 04

|

11 * 7

|

>900 |

5-6 | 940K |

AS-MBBR 05 | >1000 | 980K | ||

AS-MBBR 06 | 16*10 | >800 | 7-8 | 260K |

AS-MBBR 08 | 10 * 5 | >3500 | 15.4M | |

AS-MBBR 19 | 25 * 12 | >650 | 118K | |

AS-MBBR 37 | >800 | 5-6 | ||

AS-MBBR 38 | 25 * 10 | |||

AS-MBBR 40 | 15 * 15 | >900 | Unique | 230K |

AS-MBBR 61 | 25 * 4 | >1250 | 260K | |

AS-MBBR 64 | >1200 | |||

AS-MBBR 78 | >1600 |

Recommended accessories:

Disc Diffuser

Tube Diffuser

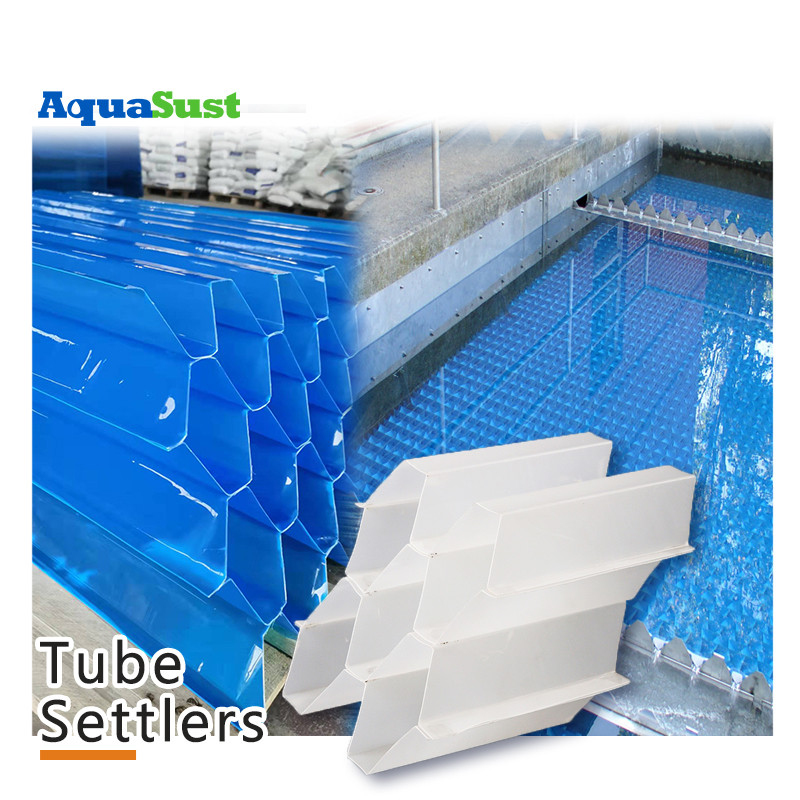

Tube Settler

Dewatering Machine

Related Products

Review

- Loading...

Please send your message to us

- Name

- *Title

- *Content

Choose AquaSust Professional Wastewater Treatment Experts

Contact Person

Please send your message to us

- Name

- *Title

- *Content