The main source of noise of Roots blower and its solution

The main source of noise of Roots blower and its solution

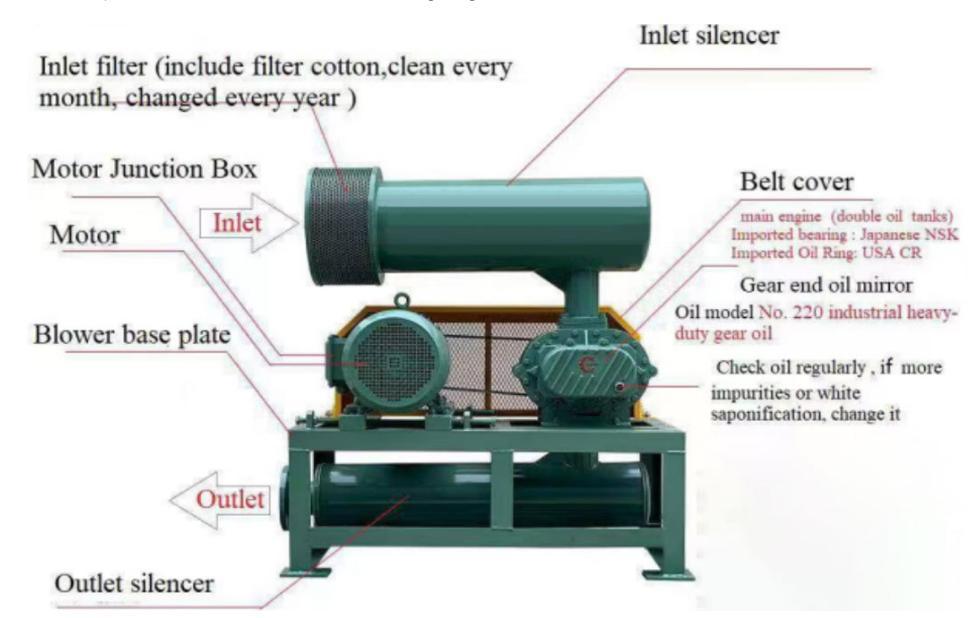

Roots blower is a kind of equipment widely used in sewage treatment field. Its working principle is to compress and transport gas through two intermeshing impellers. However, during use, users may find that Roots blower has certain noise problems. This article will analyze the main sources of Roots blower noise in detail and provide corresponding solutions.

1. Mechanical noise

(1). Friction between the impeller and the housing: Due to the small gap between the impeller and the housing or poor lubrication, the impeller rubs against the housing when rotating at high speed, thus generating noise. The solution is to adjust the gap between the impeller and the housing to ensure good lubrication.

(2). Bearing wear: Bearing wear will cause unstable vibration of the impeller during rotation, which will generate noise. The solution is to check and replace the bearings.

2. Pneumatic noise

(1). Air flow turbulence: When the gas passes through the blower, turbulence is likely to occur due to the high flow rate, thus generating noise. The solution is to optimize the air flow channel design and reduce the air flow speed.

(2). Air flow pulsation: During the operation of the Roots blower, the air flow will generate a certain pulsation, which will cause noise. The solution is to use devices such as mufflers to reduce air flow pulsation.

3. Electromagnetic noise

(1). Motor vibration: During the operation of the motor, due to the change of the magnetic field, a certain vibration will be generated, thus generating noise. The solution is to use a low-vibration motor and perform good shock absorption.

(2). Electromagnetic noise: During the operation of the motor, electromagnetic noise will be generated due to the change of current. The solution is to use a low-noise motor and perform good sound insulation.

4. Structural noise

(1). Structural resonance: When the structure of the Roots blower is subjected to external excitation, it may resonate and generate noise. The solution is to optimize the structural design and improve the stiffness and damping performance of the structure.

(2). Loose structure: During the long-term operation of the Roots blower, some structures may generate noise due to looseness. The solution is to regularly check and tighten the connection parts.

In short, the noise of the Roots blower mainly comes from mechanical noise, pneumatic noise, electromagnetic noise and structural noise. For these noise sources, we can take corresponding measures to control them to reduce the impact of noise on the environment and personnel. At the same time, regular maintenance and maintenance of the Roots blower is also an important means to ensure the normal operation of the equipment and reduce noise.