Maintenance Strategies For AquaSust Disc Diffuser: Prolonging Lifespan And Performance

1.Routine Visual Checks And Monitoring

Conducting regular inspections is the first step in maintaining the AquaSust disc diffuser. Visual checks should be scheduled monthly or quarterly to detect any physical damage such as cracks, deformation, or other signs of wear. Additionally, monitoring system parameters like pressure and airflow can reveal blockages or fouling. Implementing real-time monitoring systems can further enhance the detection of irregularities, allowing for prompt corrective actions.

2. Effective Cleaning Methods

Accumulation of biological growth, mineral deposits, and particulate matter can significantly impair the performance of disc diffuser. Regular cleaning is crucial to remove these deposits. Backwashing with clean water or using mild chemical cleaners, as recommended by the manufacturer, can effectively remove the dirt of the diffuser. It is important to avoid harsh chemicals that could damage the diffuser material. Establishing a regular cleaning schedule based on the operational load and environmental conditions will help maintain the efficiency of the diffuser.

1.Routine Visual Checks And Monitoring

Conducting regular inspections is the first step in maintaining the AquaSust disc diffuser. Visual checks should be scheduled monthly or quarterly to detect any physical damage such as cracks, deformation, or other signs of wear. Additionally, monitoring system parameters like pressure and airflow can reveal blockages or fouling. Implementing real-time monitoring systems can further enhance the detection of irregularities, allowing for prompt corrective actions.

2. Effective Cleaning Methods

Accumulation of biological growth, mineral deposits, and particulate matter can significantly impair the performance of disc diffuser. Regular cleaning is crucial to remove these deposits. Backwashing with clean water or using mild chemical cleaners, as recommended by the manufacturer, can effectively remove the dirt of the diffuser. It is important to avoid harsh chemicals that could damage the diffuser material. Establishing a regular cleaning schedule based on the operational load and environmental conditions will help maintain the efficiency of the diffuser.

Preventive Maintenance And Component Replacement

1. Establishing A Preventive Maintenance Program

A proactive approach to maintenance involves setting up a preventive maintenance program. This program should include scheduled inspections, cleaning, and component replacements based on the diffuser's usage and environmental exposure. Preventive maintenance helps identify potential issues before they become significant problems, thereby reducing downtime and extending the diffuser's lifespan. Detailed maintenance logs should be kept to track all activities and identify patterns that may indicate underlying issues.

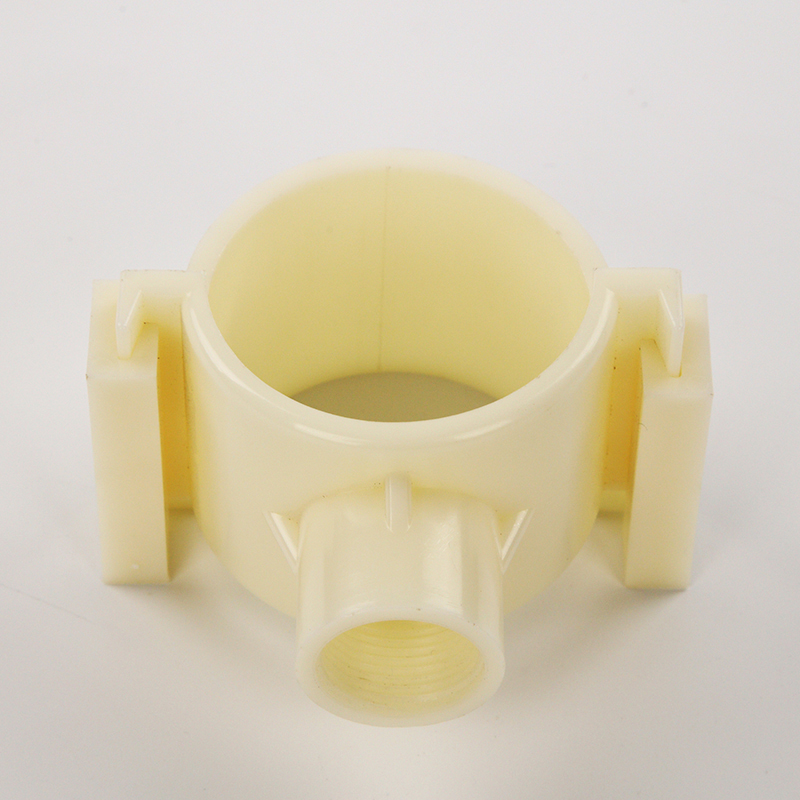

2. Timely Replacement Of Worn Components

Even with regular maintenance, certain components of the AquaSust disc diffuser will eventually wear out. Regularly assessing the condition of seals, membranes, and connectors is vital. Replacing these components as they show signs of wear ensures the diffuser continues to function optimally. Keeping an inventory of essential spare parts can facilitate quick replacements, minimizing operational disruptions. Additionally, periodic reviews of the replacement frequency can help in fine-tuning the maintenance schedule to better suit the operational demands.

Implementing a comprehensive maintenance strategy for the AquaSust disc diffuser involves regular inspections, effective cleaning, preventive maintenance, and timely replacement of worn components. By adhering to these practices, wastewater treatment facilities can ensure the prolonged lifespan and optimal performance of the AquaSust disc diffuser, leading to more efficient and reliable operations.