How to Install Disc Diffuser at the Workplace

1.1 Gas Supply: The disc diffuser is usually connected to a gas supply line that provides compressed air or oxygen through an air pump or gas supply system.

1.2 Bubble Generation: Gas enters the interior of the disk diffuser from the gas supply line. Inside the disk diffuser, the gas passes through tiny holes or apertures and is released into the water to form small bubbles.

1.3 Bubble Floating: The generated bubbles float to the surface of the water due to buoyancy. During the uplift process, the bubbles come into contact with pollutants in the water column and transfer oxygen to the water.

1.4 Oxygen Dissolution: As the bubbles rise to the surface, they interact with pollutants in the water and release oxygen in the water. This increases the oxygen content of the water column and facilitates the growth and metabolism of microorganisms in the water.

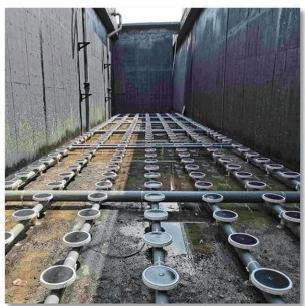

1.5 Circulation: Disc diffusers are usually installed at the bottom or side of a body of water to ensure that the air bubbles are evenly distributed throughout the body of water. This even distribution of air bubbles helps to improve the oxidizing conditions of the water body and promotes the even distribution and activity of microorganisms in the water.

2.1 Preparatory Work: Before starting the installation, make sure you have the required tools and materials, such as wrenches, screwdrivers, pipe connectors, etc. Also, read the installation instructions carefully to understand each step.

2.2 Select Installation Location: Select a flat, firm surface on which to install the disk diffuser. Make sure the location is far enough away from the edge of the pool or body of water to avoid interference from air bubbles and water flow.

2.3 Determine the Mounting Height: Determine the mounting height of the disk diffuser based on the recommendations provided by the manufacturer. Normally, the mounting height should be such that there is a distance between the bottom of the diffuser and the surface of the water to ensure that oxygen can be adequately dissolved in the water.

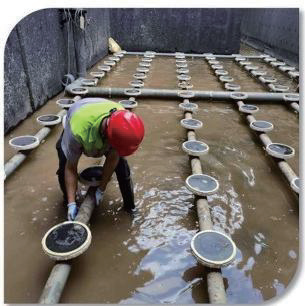

2.4 Secure the Diffuser: Securely install the disk diffuser in the selected location using appropriate fixtures or brackets. Ensure that it is securely mounted and will not move or wobble due to water flow or other factors.

2.5 Connecting Piping: Use piping connectors to connect the disk diffuser to the air supply piping. Ensure that the connections are tightened securely and that any holes that may exist are filled with sealant or packing.

2.6 Perform a Test: After the installation is complete, turn on the air supply and observe that the disk diffuser is working properly. Check for uniform and adequate bubble production to ensure that the diffuser is operating as expected.

2.7 Regular Maintenance: Periodically check the operating condition of the disk diffuser and clean and maintain it as needed. Replace damaged parts promptly and clean the surface of the diffuser periodically to ensure optimum performance.

Disc diffuser is a widely used equipment in various water treatment fields, and its application areas include but are not limited to the following:

3.1 Wastewater Treatment Plants: Disc diffusers are commonly used in aeration or aerobic tanks in wastewater treatment plants to inject oxygen into the water body, promote the growth of microorganisms in the wastewater, and degrade organic substances, thus realizing the treatment and purification of wastewater.

3.2 Wastewater Collection Systems: Disc diffusers can also be installed in wastewater collection system sewage pipes to provide oxygen during the flow of wastewater, which helps to reduce organic deposits and odors in the pipes.

3.3 Ponds and Lakes: Disc diffusers can be installed in ponds, lakes, and other water bodies to improve the oxidizing conditions of the water by injecting oxygen into the water body, promoting the growth of microorganisms in the water and improving water quality.

3.4 Aquaculture: In the aquaculture industry, disc diffusers are commonly used in fish ponds, shrimp ponds, and other aquaculture water bodies, used to provide an adequate supply of oxygen to ensure that the aquaculture water bodies in the healthy growth of fish or shrimp.

3.5 Industrial applications: Disc diffusers are also widely used in the industrial production process of water treatment, such as pharmaceutical, chemical, food processing, and other fields, for the treatment of wastewater, and water purification.

In general, the disc diffuser plays an important role in all kinds of water treatment fields, through the provision of sufficient oxygen supply, to promote the growth and activity of microorganisms in the water body, to achieve the purpose of purifying water quality and improving the environment.