Aeration Disc Design and Optimization: How to Achieve Higher Oxygen Transfer Efficiency

Aeration Disc Design and Optimization: How to Achieve Higher Oxygen Transfer Efficiency

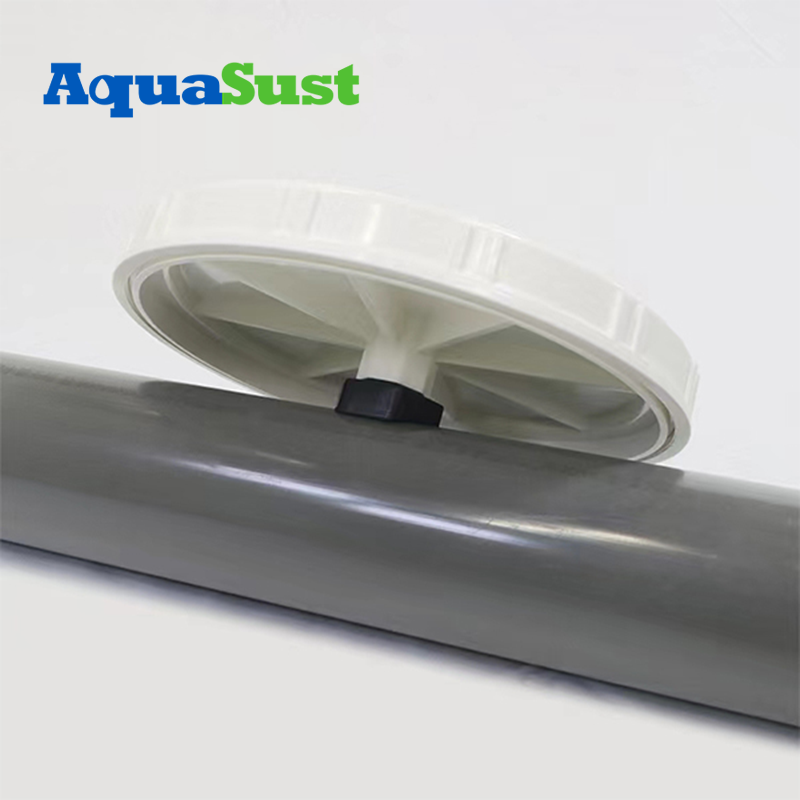

The aeration disc is widely used in wastewater treatment and water oxygenation systems, designed to transfer air effectively into water to increase dissolved oxygen content, promote microbial metabolism, and break down pollutants. The design and optimization of aeration discs are critical factors influencing their oxygen transfer efficiency (OTE), making improvements in aspects like structure, material, and bubble distribution essential for overall performance. This article dives into the key elements of aeration disc design and optimization to maximize oxygen transfer rates.

The Importance of Oxygen Transfer Efficiency

Oxygen transfer efficiency is a core metric for evaluating the performance of aeration equipment, typically represented by the rate of oxygen mass transfer. In wastewater treatment systems, higher oxygen transfer rates mean better pollutant removal and reduced energy consumption. Therefore, improving the oxygen transfer efficiency of an Disc Diffusercan enhance water treatment performance while lowering operating costs.

Key Design Factors Affecting Oxygen Transfer Efficiency in Aeration Discs

1.Pore Size and Distribution Density

Pore size and density significantly impact bubble formation. Smaller pores typically produce finer bubbles, increasing the air-water interface area and improving oxygen mass transfer rates. The distribution density affects bubble uniformity, and both overly sparse and overly dense arrangements can affect transfer performance. Optimizing pore size and density based on experimental data is crucial to achieve optimal results.

2.Material Selection for the Membrane

Disc Diffusermembranes are typically made from silicone, EPDM, or other durable materials with excellent corrosion and heat resistance. These materials also maintain elasticity, reducing bubble adhesion on the membrane. The use of high-performance polymers is increasingly common, as they prolong disc life and enhance oxygen transfer efficiency.

3.Disc Surface Structure

The geometric design of the disc surface also impacts bubble distribution. An optimized design ensures more uniform airflow and prevents "short-circuiting," allowing bubbles to be released evenly. This can be achieved through Computational Fluid Dynamics (CFD) simulations, identifying the best airflow channels and bubble release points.

4.Control of Airflow Rate

Airflow rate directly affects the performance of the aeration disc. Excessive airflow causes bubble rupture, increasing energy use and reducing efficiency, while insufficient airflow leads to bubble concentration issues. Adjusting airflow rates through flow regulation systems can help balance energy use and mass transfer efficiency.

How to Improve Oxygen Transfer Efficiency through Optimized Design

1.Utilizing Microbubble Technology

Microbubbles provide a higher air-water contact area, enhancing oxygen transfer efficiency. Using finer pores or designing microbubble generators can significantly increase oxygen utilization.

Performance Reference:

· Oxygen transfer efficiency can improve by approximately 20%-30% with microbubble technology.

· In systems requiring high dissolved oxygen, such as deep water, microbubbles can increase oxygen utilization from the traditional 10%-15% to 25%-40%.

2.Optimizing Inlet Position

Changing the inlet position on the Fine bubble Diffuserimpacts gas distribution on the surface. In multi-disc aeration systems, adjusting inlet positions can ensure an even air supply to each disc, enhancing oxygen transfer efficiency.

Performance Reference:

· Proper inlet design can improve oxygen transfer rates by an average of 10%-15%.

· In large-scale treatment facilities, overall oxygen utilization efficiency can increase by 5%-10%.

3.Applying Variable Frequency Control Systems

3.Applying Variable Frequency Control Systems

Different water qualities and treatment stages require different aeration demands. With a variable frequency control system, airflow can be dynamically adjusted according to actual needs, minimizing unnecessary energy consumption while boosting aeration efficiency.

Performance Reference:

· Variable frequency control can reduce operational costs by 10%-20%, with oxygen transfer efficiency increased by 5%-10%.

· Energy savings average around 15%, with a boost in aeration efficiency by approximately 10%-15%.

Conclusion

The design and optimization of aeration discs involve a multifaceted engineering approach, considering factors like pore size, membrane material, disc structure, and airflow control. Through these enhancements, aeration discs can achieve higher oxygen transfer efficiency, realizing greater economic and environmental benefits in wastewater treatment, aquaculture, and related fields. With the integration of new materials and intelligent control technologies, the future of Fine bubble Diffuser technology holds promising potential in advancing eco-friendly water treatment solutions.